What Is a Concrete Pool?

A concrete pool is an extremely tough and flexible form of swimming pool that is constructed using either sprayed concrete or poured concrete. A concrete swimming pool is fully customisable in terms of shape, size and depth, unlike prefabricated options that are often limited in all these.

Types Of Concrete Pools

Concrete pools come in a variety of types, with each having its own type of construction and advantages. The gunite concrete pools, as well as shotcrete concrete pools, among other concrete pool designs with cast concrete, are the available options of pool structures that homeowners can choose to suit their budget and design needs.

Gunite Pools

A gunite pool is constructed by spraying a dry concrete mix, where water is forced through it under pressure. The method of construction provides strong walls, resulting in the possibilities of unique shapes and the creation of custom concrete pools, as well as offering more versatility and long-term resistance to wear and tear.

Shotcrete Pools

A shotcrete pool is constructed with a wet concrete mix applied to the place by a high-pressure hose. This technique produces robust, watertight construction, and a shotcrete concrete pool is an exceptional option for homeowners who seek versatile, long-lasting and aesthetically pleasing bespoke pool constructions.

Cast Pools

Cast concrete pools are produced by pouring concrete into moulds or forms, like traditional pools. Although not as adaptable as spraying practices, they are nonetheless durable and sturdy. Modern builders also provide precast pools for a faster installation.

Benefits of Concrete Pools

The numerous advantages of having a concrete swimming pool are versatile design, durability and high-quality finishes. Concrete gives homeowners an opportunity to attain luxury aesthetics through a variety of shapes and styles (free-form pool designs and traditional rectangular shapes) in addition to superior functionality and lasting performance.

Custom Shapes and Sizes

Among the best benefits of custom concrete pools is that they can be shaped and sized however you like. Homeowners may choose to have a geometric pool or a free-form pool, but the fact remains that pool customisation will enable the product to suit the individual lifestyles, landscaping features, and aesthetic demands.

Exceptional Durability

An established in-ground concrete pool offers outstanding durability, outliving many alternatives. Depending upon how it is designed, a gunite concrete pool or a shotcrete concrete pool, this construction provides superior resistance against wear-and-tear, promising the homeowner with an activity for swimming which is sure to last for years.

Luxury Finishes

Concrete pools are distinguished by the various concrete finishes they offer. One can use tile on pebble and polished surfaces. These finishes add character with beauty, longevity, and safety so that a homeowner can easily align their concrete swimming pool with style and elegance at par with a luxurious centrepiece.

Higher Depth Potential

In contrast to vinyl or fibreglass, a concrete swimming pool offers many depth possibilities. From shallow leisure areas to deep sections, with this structural flexibility, the homeowners can have an ideal in-ground concrete pool design suited for recreation, workout, and even entertaining needs.

Enhanced Aesthetic Appeal

Designer concrete pool, free-form or geometric style, stands unrivalled in aesthetic allure. The homeowners enjoy pool customisation with unique contours and decorative concrete finishes that will turn an ordinary backyard into a luxurious oasis with everlasting charm.

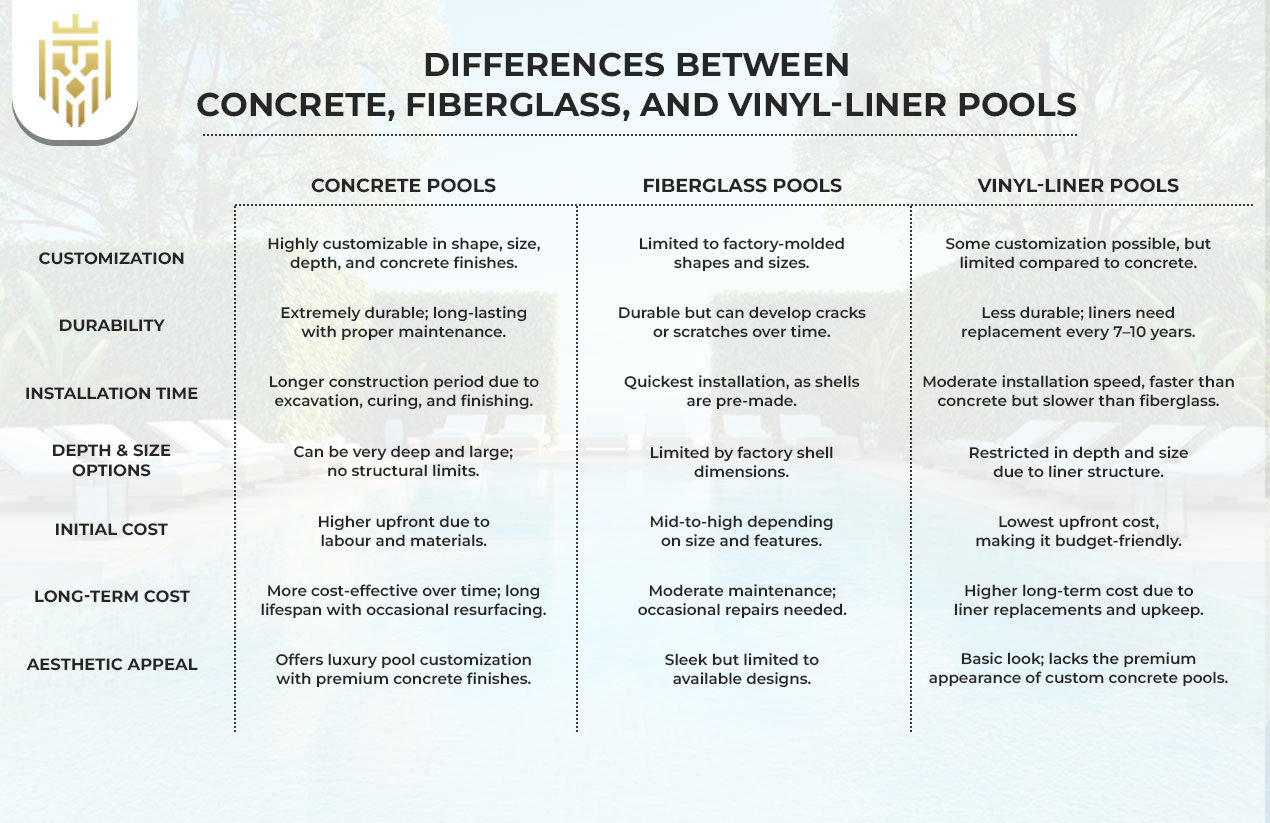

Difference Between Concrete Pools and Other Inground Pool Types

A concrete pool offers more depth, durability and customisation than fibreglass or vinyl. Alternatives may be quickly installed, but only a luxury concrete finish and pool customisation of custom concrete pools provide flexibility of design, long-term performance, and beauty.

Concrete vs Fiberglass Swimming Pool

Comparing concrete and fibreglass swimming pools, the former is more customisable and durable, whereas the latter is easier to install. A concrete pool can be deeper and larger in build and is not limited by the factory-made form of fibreglass, limiting personalisation and creative build freedom.

Concrete vs Vinyl-Liner Swimming Pool

A concrete swimming pool, unlike a vinyl-liner pool, is durable and easily customisable in terms of finishes. Although vinyl might cost less initially, the concrete pools are more cost-effective in the long term due to the better construction quality, customised possibilities, and the posh look of concrete pools.

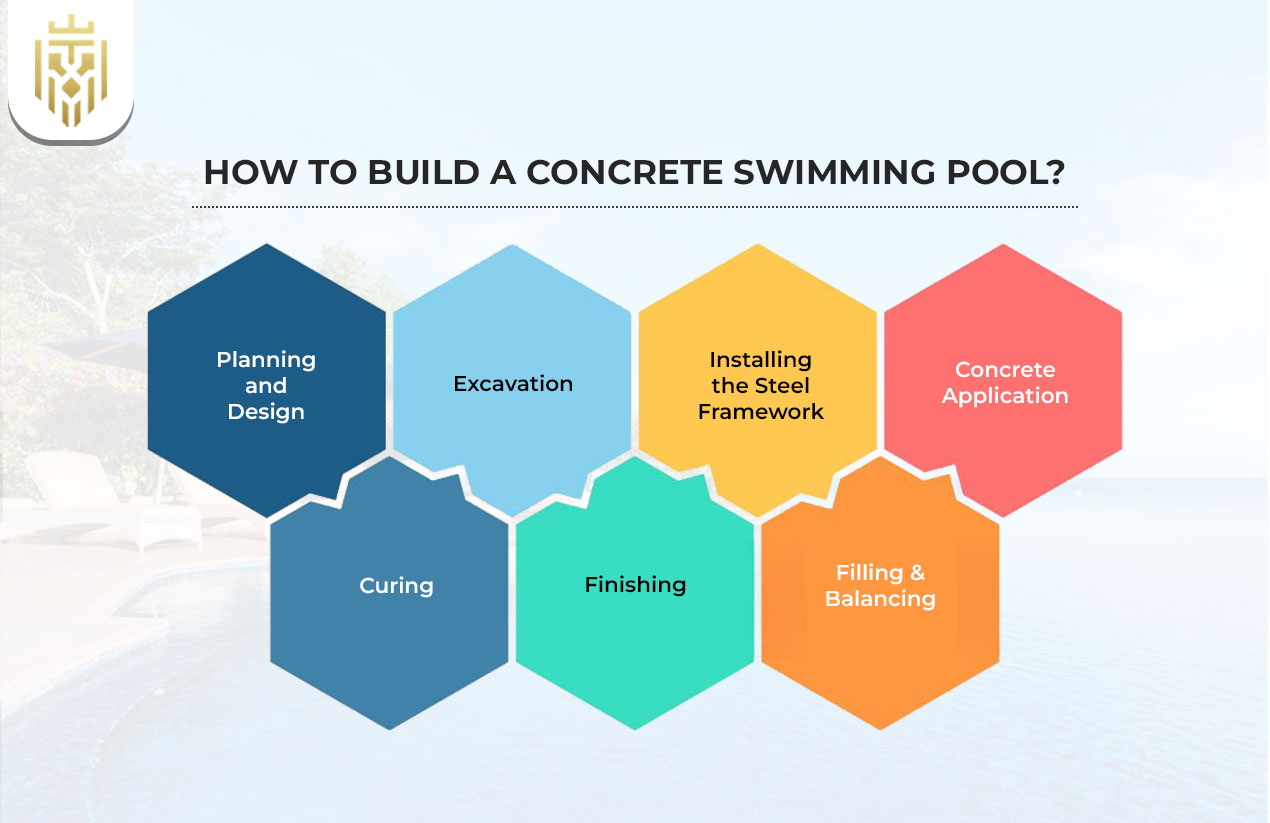

How To Build A Concrete Swimming Pool?

Before the construction of a concrete swimming pool starts, it is important to understand how to construct it. This is done through thorough planning, excavation, installation of frameworks, application of concrete, curing, finishing, and balancing of the concrete. All these stages guarantee the safety, durability, and aesthetics of the final concrete pool to the homeowners.

Planning and Design

The initial process in how to build a concrete swimming pool includes planning and design. Residents work with designers to determine size, depth, and shape. At this point, it is important to customise the pool, and the finished custom pool fulfils the lifestyle preferences of the individual.

Excavation

Excavation is done to prepare the ground where an in-ground concrete pool will be installed; the land is removed and shaped to fit the in-ground concrete pool. This process guarantees proper depth and placement and confidence in the cement layers that set the pool shell.

Installing the Steel Framework

A steel structure is built to strengthen the concrete pool. This reinforcement gives it strength and flexibility so that the concrete shell can resist the pressure of the soil. Proper installation in this case gives the framework of a permanent custom concrete pool with stability and strong resistance.

Concrete Application

In this step, the gunite pool or shotcrete pool method is applied to spray concrete into the steel structure. Both can make robust shells, although shotcrete concrete pools are often preferred due to consistency and easier structural finishings.

Curing

The curing phase plays a pivotal role in the strength of a concrete swimming pool. Moisture is provided to harden the concrete throughout the process over several weeks. Effective curing will make the cast concrete structure or sprayed structure durable, crack-free, and long-lasting.

Finishing

The finishing stage involves the application of concrete finishes such as plaster, tile or pebble. These improve the appearance, texture and strength of the concrete pool. Rich mosaics, delicate tones, and finishing make the pool more beautiful and luxurious.

Filling & Balancing

The last is filling the concrete swimming pool with water and balancing the chemicals. Proper balancing provides safe swimming conditions and increases surface life. Upon completion, the in-ground concrete pool is ready to use, and it provides lasting enjoyment.

Maintenance Tips for Concrete Pools

Weekly brushing and checking chemical balance, and periodically resurfacing a concrete swimming pool. This means routine vacuuming to keep the water clear and polishing the concrete surface every 10-15 years to maintain a safe, sound, and attractive appearance.

Brush the Walls Weekly

Cleaning and brushing the interior walls of a concrete pool once each week prevents algae build-up and surface stains. Whether it is a gunite concrete pool or a shotcrete concrete pool, brushing on a regular basis ensures smooth surfaces and ensures that the pool looks clean and appealing.

Check pH and Chlorine Levels

The pH and chlorine levels should be maintained in concrete swimming pools. Precise water chemistry guards against corrosion, scale formation and health hazards. Routine maintenance ensures the beauty and the lifespan of your swimming pool.

Vacuum Regularly

Vacuuming a concrete pool helps get rid of dirt and debris that cannot be removed through brushing. Custom concrete pools are maintained using both manual and automatic vacuums. This action will improve the clarity of the water, preserve it, and ensure the pool is pleasant and usable throughout the year.

Resurface Every 10–15 Years

A concrete swimming pool may need to be resurfaced every 10-15 years to regain its beauty and functionality. This renovation of concrete finishes helps to avoid cracking or coarseness, giving a safe swimming experience as well as a remodelled look to your luxurious in-ground concrete pool.

FAQs

1) What Is a Concrete Pool?

Concrete pools are permanent, customisable swimming pools constructed out of sprayed or poured concrete. A concrete swimming pool has the flexibility of design, depth, and finishes; it is a long-lasting value, unlike prefabricated options.

2) How to build a concrete swimming pool?

The construction of a concrete swimming pool will require planning, excavation, reinforcement using steel, concrete application, curing and finishing. All of these steps make your in-ground concrete pool durable, versatile, and aesthetically appealing.

3) What is the difference between a concrete and fiberglass swimming pool?

A comparison of a concrete swimming pool and a fibreglass swimming pool reveals that concrete pools can be deeper and in custom shapes and construction, whereas a fibreglass pool is restricted to factory shapes and mouldings but installs more rapidly. Concrete offers more flexibility in pool customisation.

4) What are the benefits of concrete pools?

Advantages of concrete swimming pools are that they can be of any design, their errors can be fixed, they have high-quality concrete finishes and customisation. Concrete pools offer superior durability and cost-efficiency and can be designed as freeform pools or luxury pools.

5) What are the different types of concrete pools?

The principal varieties of concrete swimming pools are gunite pools, shotcrete pools, and cast concrete pools. Other constructors prefer to use precast pool technologies, each having its own strengths in terms of strength, durability, and design options.